How to Cut | Connect | Power COB LED Strip Lights

Tips for cut and reconnect light strips. how to cut led strips, how to connect multiple light strips together, and how to power yiford cob led strip lights.

Neon LED light strips innovate through material science and functional integration, overcoming traditional LED limitations in protection, safety, and adaptability. Their multi-scene compatibility and cost efficiency make them a pragmatic yet aesthetic solution for modern lighting design.

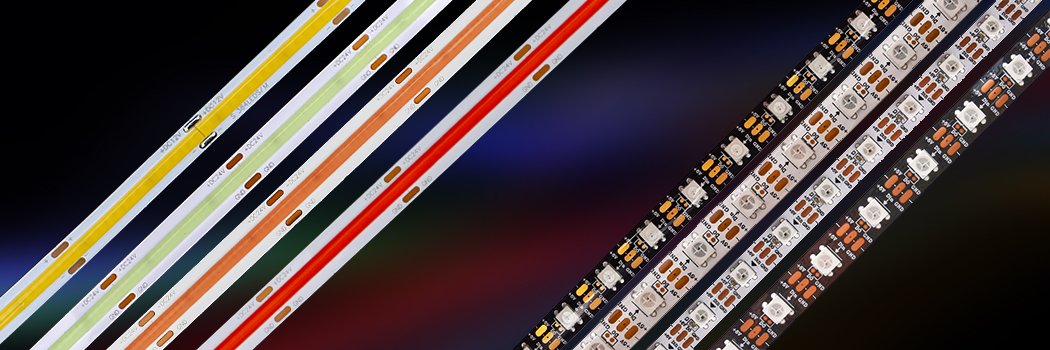

LED strip lights are versatile lighting solutions that offer energy efficiency, long lifespan, and customizable designs. They come in two main types: COB (Chip-on-Board) LED strip lights, which provide a continuous, uniform light output ideal for seamless applications, and SMD (Surface-Mounted Device) LED strip lights, known for their flexibility and variety in brightness and color options. Both types are easy to install and can be used for accent lighting, task lighting, or decorative purposes, enhancing any space while reducing electricity costs.

YIFORD offers a wide range of solderless connectors designed for LED strip lights, simplifying installation without the need for soldering. Our product lineup includes board-to-board, board-to-wire, wire-to-wire, L-shaped, and T-shaped connectors, with hundreds of styles available. Compatible with nearly all widths and models of LED strip lights on the market, our connectors ensure reliable connections for both DIY enthusiasts and professionals.

Silicone light strips are very soft and can be bent, twisted, and stretched freely, suitable for complex design and installation environments. It has strong weather resistance, is not easy to crack, and has a long service life. Silicone light strips are usually designed with low voltage, which improves the safety of use. In addition, silicone material itself has characteristics such as fire resistance, gas corrosion resistance, and UV protection, which can work stably in harsh environments.

Light Accessories

Light Accessories

The LED controller is a chip that processes and controls the switches at various positions in the LED light circuit. The controller controls the driving circuit according to the pre-set program to make the LED array emit light in a regular manner.

High quality anodized LED aluminum channels for LED strip lights, also known as led aluminum profiles or led aluminum extrusions, are your best choice of installation and function companion for LED strip light projects.

They are popularly used as LED light strip diffuser to achieve better diffusion and set creative lighting effects, and work as LED strip mounting channel to assist LED strip light installation.

LED light channel with diffuser is often surface mounted for under cabinet lighting. Ceiling LED strip channel, recessed LED channel, and corner LED channel are among the top choices for LED strip light application.

The aluminum channels provide housing and protection for LED strips. Working as heat sinks, they greatly improve the heat management of LED strips.

This article aims to introduce some basic knowledge of led aluminum profiles to you, and help you choose high-quality led aluminum profile products for your projects.

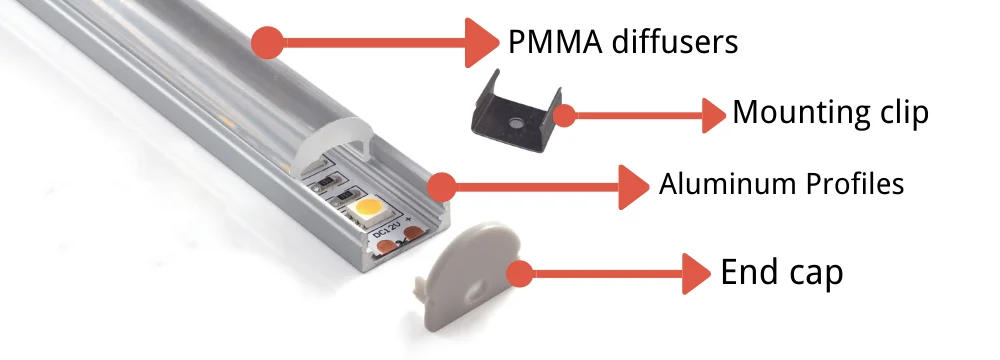

LED aluminum profiles are also known as LED extrusion profiles, Common parts include aluminum profiles, PMMA diffusers, end caps and mounting clips. They are extruded lighting fixtures for LED strips of different shapes and sizes.LED aluminum profiles are assembled with LED light strips and other accessories, which are widely used in the field of LED lighting.

It is using recessed clamps or screw to fix the profile into the ceiling

It is installed with a wire rope suspended from the ceiling

It is used in corner of the wall, kitchen, etc

It is using plastic or metal clips to fix the profile on the surface of the items

Small size, used for furniture, cabinets, etc., often use 5mm/8mm wide light strips

Large size, large luminous area, used for main lighting in space.

Medium size, often used for wall decoration, molding, contour decoration, etc.

Medium size, the shape is more complex, with lace, it is often used for stairs, artistic modeling, etc.

LED Aluminum Profile = Aluminum Extrusion + Diffuser.

Aluminum extrusion and diffuser are two very important parts of led aluminum profiles. (Other small accessories such as end caps are also part of the led aluminum profile) But these two main parts determine the quality of the led profile. So when we talk about the quality of led aluminum profiles, the main focus is on aluminum extrusions and plastic diffusers.

The LED aluminum profile is designed to fully tap the potential of installation and connection, providing designers, architects and engineering parties with flexible solutions for space and lighting design, and is the best choice for LED strip project installation and functional companions. We can find them used in small cabinets as well as LED linear lighting in large spaces such as home applications, office lighting, supermarkets, shopping malls and hotels. Widely used as LED light bar diffuser to achieve better diffusion and set creative lighting effects, and as LED light bar installation channel to assist LED light bar installation. The aluminum channels provide housing and protection for the LED strip, and as heat sinks, they greatly improve the thermal management of the LED strip.

If a buyer is going to buy led aluminum profiles, he should have a good understanding of his lighting project before buying.

There are hundreds of Led aluminum profiles on the market. When we are faced with so many options, we can be completely confused. What kind of led aluminum profile should we choose?

This article will help if you are a reseller in your country.

This article will also help if you are shopping for LED aluminum profiles for personal home use.

If you are a LED linear light manufacturer in your country and you want to buy LED aluminum extrusions for your company to manufacture LED linear lights. After reading you will also find some useful information.

Always make sure that the inner base of the led aluminum profile is wider than the width of the led strip so that the led strip can be smoothly installed into the profile.

There are various options for internal channel widths. Generally, the size of aluminum c-slot or aluminum u-slot varies from narrow to 5mm to wide to 50mm or more, suitable for various light strips, such as 5mm, 8mm, 10mm, 12mm and other light strips. With the development of the lighting market in recent years, their internal dimensions have become wider, such as 20mm, 30mm, and even 100mm. However, due to the actual lighting project, the width of LED aluminum profiles is now more than 100mm.

The depth of led aluminum may be limited by the installation space. The depth of the LED strip channel has a double impact on the installation and use of the strip.

The depth of the LED strip channel needs to match the depth of the mounting slot. Remember that the thickness of the mounting surface will limit the depth of the groove.

The depth of the aluminium profile determines the distance between the LED strip and the diffuser. Distance affects the uniform distribution of light. For the same LED strip, the darker the profile, the more uniform the light distribution. If the contour depth is constant, the higher the LED density, the better the light distribution effect of the LED strip.

Shallow depths with narrow width LED profiles are always suitable for small areas, but deeper sized LED profiles will be applied to walls or ceilings. From our case, we produce many wide and deep LED profiles for ceilings. Such as 54x70mm, 100x75mm, 75x75mm, etc.

The common lengths on the market are 1 meter, 2 meters, 2.5 meters, 3 meters, etc. Before choosing your profile length, you should clarify which shipping method you prefer to ship your led aluminum profiles. By air or sea. If you choose air freight, you’d better choose the length within 3 meters to avoid extra freight. But if you choose economical sea freight, the length will be a free choice. You can ask your supplier to customize any length available for container loading.

Most of LED aluminum profiles are U-shaped channel steel, and U-shaped aluminum profiles are widely used. But there are also V-shaped channels, round, wavy. Different shapes of LED aluminum profiles are available for different installations. For example, corner aluminum profiles are suitable for corner installation. Aluminum u-groove can have wings or no wings, also called flange. LED profiles with flanges help cover uneven grooves.

Which shape of led profile is the best choice, ask yourself where you want to install the led profile and what lighting effect you want to achieve. The better you know about your lighting project, the better choices you’ll make.

The housing of the LED aluminium profile provides protection against dust, moisture and UV radiation for the LED strip inside the aluminium profile. The cover can also be used as a diffuser or lens for the LED strip. The cover can be clear, frosted or creamy white. Each type of cover produces different lighting. The clear cover is transparent, allowing light to pass through without reducing brightness. The frosted cover is translucent, reducing the brightness slightly. But its main function is to achieve uniform light and avoid glare. The use of milky white cover can realize pointless light emission, that is, when the LED light strip in the aluminum profile is turned on, the LED cannot be seen. If you don’t like seeing individual LED light spots and just want to see spotless lighting, choose LED profiles with frosted covers or bras, paired with suitable LED strips, with a LED density of at least 120 LEDs per meter.

In addition, the profile cover provides the LED strip inside the aluminium profile with a strong resistance to weather conditions, dust, water droplets and UV radiation.

To help users use LED profiles easily, we provide a variety of mounting accessories for various LED profiles, such as mounting brackets, 3M tape, fasteners, etc.

Mounting brackets. Mounting brackets, also known as mounting clips, ensure easy and safe installation. They can also be used as a connector between two aluminium profiles.

3M tape. For surface mounting of LED profiles you can use 3M Double Sided Tape (not included but can be found in our 3M Double Sided Tape section).

end cap. Aluminium profiles come with standard end caps. They fit profiles to further protect them from dust and other harmful elements and also give the profiles a nicer appearance.

Other accessories for LED profiles. In addition to the above accessories, there are also aluminum profile connectors, fasteners, suspension devices, suspension cables, etc. They help make your professional installation as easy as possible.

LED strip connector. Note that some LED strip connectors are too large to fit into the aluminum track channel. Find out the inside dimensions of the anodized aluminum tube and choose the right width LED connector.

Anodised silver, painted white and black are the three basic colours for LED aluminium profiles. Black can also be achieved by anodizing, but the cost of anodizing black is a bit more expensive than jet black. Three colors seem too few for practical operating conditions. There is always a project that needs a special color. Such as dark brown, gold, blue, etc. Always remembering color is not difficult to achieve, but quantity and cost will be the first consideration.

The best aluminum alloy for making led aluminum profiles is 6063 T5. In addition, the anodized layer of the aluminum profile should reach 8-13 microns, and the paint layer should reach 60-80 microns. If the oxide layer is thicker, the profile will be hard and not easily deformed. It also has better corrosion resistance.

For the cover plate, the thickness of the cover plate we often make is 1.2mm ultra-thin and 1.4mm large.

The raw material of the cover we choose high quality Panlite and other brand materials.

Do you have any ideas for LED profile design? If you have some knowledge about the structure design of LED profiles, you will choose LED profiles with simple structure design but good quality from the market. For example, an aluminum profile with a removable middle plate is a better design than a non-removable one. With the removable middle part we can easily put the LED driver into the LED profile.

How much do you know about led aluminum profile suppliers in China?

Do they have an aluminum plant or a plastic extrusion plant? Ask for a factory tour and you’ll find out.

The amount of inventory has a great impact on the delivery time. The raw materials of aluminum profiles are generally purchased by tons. One ton of aluminum materials can produce several kilometers of LED aluminum profiles. For styles, if each model is only one ton, the inventory is also very large, and powerful companies will prepare some inventory to meet the needs of small orders, and the delivery time is also fast.

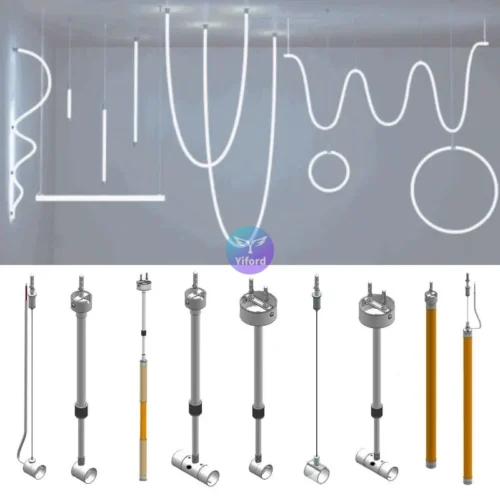

There are different installation methods according to our actual usage. The most common type of mounting we see is surface mount. Usually, led aluminum profiles are fixed by brackets on both sides of the profile. The second popular installation method is embedded. Before installing this recessed led aluminum profile, we need to make grooves in the wall, ceiling or other surfaces that need to be recessed. This installation method makes the led aluminum profile integrated with the wall or ceiling without any protrusion. Pendant led aluminum profile for hanging use. Using hanging wire, hang the led aluminum profile under the ceiling in offices, supermarkets, hotels and other application places. In complex lighting projects, there are mixed installation methods of led aluminum profiles. Such as surface mount combined with groove. Recessed LED aluminium profile combined with pendant LED aluminium profile.

Most led aluminum profiles are U-shaped with or without flanges. In addition, there are V-shaped LED aluminum profiles specially designed for corner LED lighting use. And there are round tubular led aluminum profiles designed with semi-circular plastic diffuser or 360 degree plastic diffuser. LED aluminum profiles can also be bent into different shapes for LED lighting, that is, bendable led aluminum profiles. Another popular LED aluminum profile is the round LED profile for pendants.

Led aluminum profiles are generally made into 2 meters, 2.5 meters, 3 meters long, and sometimes can be made into 6 meters long. In order to facilitate storage and transportation, the company generally uses 2 meters as the standard length for preparation. In actual use, led aluminum profiles will be cut into suitable lengths for use. For a professional led aluminum profile company, we have professional cutting machines to cut led aluminum profiles. But for small home users, you can cut the LED outline with a hand saw. Whether it is a professional led profile company or a small home user, we have some points to pay attention to when cutting led profiles:

The first step is to measure the length of the groove or the surface on which the LED aluminum profile will be mounted. And keep in mind that the led aluminium profile should be a few millimeters shorter than the groove.

There is one more step we have to do first before we cut the LED outline. That is, snap the plastic cover into the aluminum profile and cut the aluminum and PC together. Only then can we keep both parts the same length. If we cut the two parts separately, we might end up with lids and aluminum profiles of different lengths.

How long do you plan to keep the LED aluminum profiles for installation? Measure it and make a mark on the outline. By doing this step, you will avoid any cutting mistakes.

Measure the end caps and cut the plastic caps We should know that the end caps take up some space when we install them into the LED aluminum profiles. So the total length of the plastic cap includes the size of the two end caps, and the length of the plastic cap needs to be readjusted. Cut off a few millimeters equal to the size of the two end caps. Going through these steps will make the installation of your led aluminum profile much easier.

Yiford specially designed LED strip light aluminum channels can be installed perfectly in grooves of cabinets, ceilings, stairs, walls, and floors. The resulting lighting is aesthetically beautiful and stylish due to its elegant linear shape, spotless diffusion, and low profile, and unobtrusive contours.

Buy led aluminum profile now? review more from LED Aluminum profile

Surface Mount LED Aluminum Profiles (Extrusions)

Surface-mounted aluminum profiles using plastic clips or metal clips to fix the profile on the surface of the items. its come in a variety of shapes and sizes.

the smaller aluminum profiles for task and decorative lighting purposes. the larger surface-mounted aluminum profiles can house high-output LED strips and be used for general lighting purposes.

Easy and convenient used. We use high-quality aluminium profile for strip lights. Our surface mounted led extrusions are made of high quality 6063 aluminum alloy

Our surface-mounted aluminum profiles are sold as a complete kit and include your choice of lens, end cap, install clips and so on.

In addition to the role of heat sinks to enhance heat dissipation, LED aluminum grooves, together with LED strips, are an essential element of personalized lighting that many lighting

designers love. They have countless advantages.

The aesthetic appearance of the aluminum channel’s improved linear lighting creates a wonderful lighting shape for the space. When installing the light strip, its contour can add layering to the indoor environment.

A house with a simple structure can have amazing results if the shape of linear lighting is applied well. It can be said that the light strip is a small makeup at home! For commercial use, it displays more attractive merchandise. Installed at home, very elegant. On stage, very eye-catching.

The LED aluminum channel acts as a heat sink, which absorbs the heat generated by the LED strip during operation and dissipates it into the air through the surface of the channel. An improved thermal management system extends the life of the LED strip.

The anodized aluminum tube provides a solid housing for the LED strip, which is protected from water, dust, UV radiation, weather conditions and unwanted influences. For example, it can be used for strip lighting in splash areas.

Aluminium profiles can be seamlessly embedded into recesses in cabinets, stairs, walls and floors. They take up very little space, but provide lighting precisely where you want it to be, without the sight of bulky light fixtures.

The overlay of the aluminum extrusion is often referred to as an LED strip diffuser. It can be frosted or opal to provide the best light diffusion for a perfectly spotless and more even lighting effect and avoid glare.

Aluminium profiles can help to mount LED strips in different ways. Some surfaces are uneven, rough or too oily for LED strips. Aluminum channels facilitate mounting LED strips to these surfaces. The aluminium channel also acts as a bridge to fill the gap between two separate mounting surfaces.

DIY lighting shapes are easy. Aluminium channels can easily be cut at different angles at the ends for angular connections to create square, triangular, L-shaped or tree-shaped lighting designs. Create more personalized lighting with ease.

The inner light strip can be easily removed and replaced in case the user wants a different color light strip.

The LED strip channel is designed for low voltage strips. It is very safe to install and use.

Tips for cut and reconnect light strips. how to cut led strips, how to connect multiple light strips together, and how to power yiford cob led strip lights.

The transparent crystal connector is dedicated to COB or SMD flexible light strips, seamless connection. no connection breakpoint.

LED controllers, also called LED light controller, are the necessary parts to achieve remote control the lighting effects for LED strip and LED lights, including adjust brightness level, select color, and switch color-changing modes.