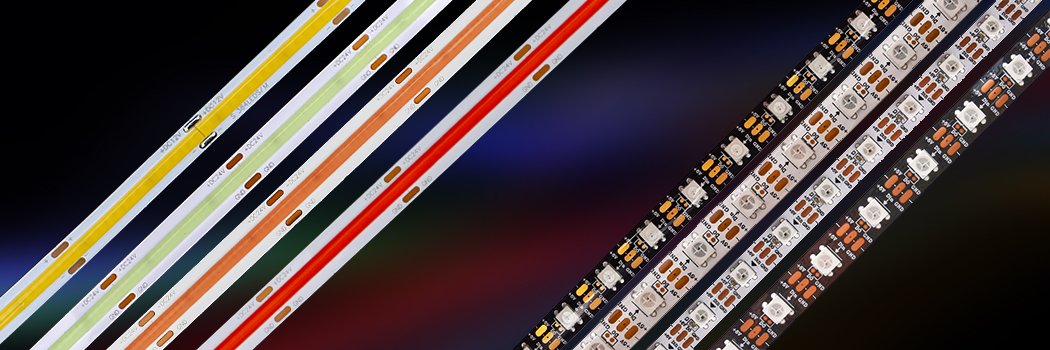

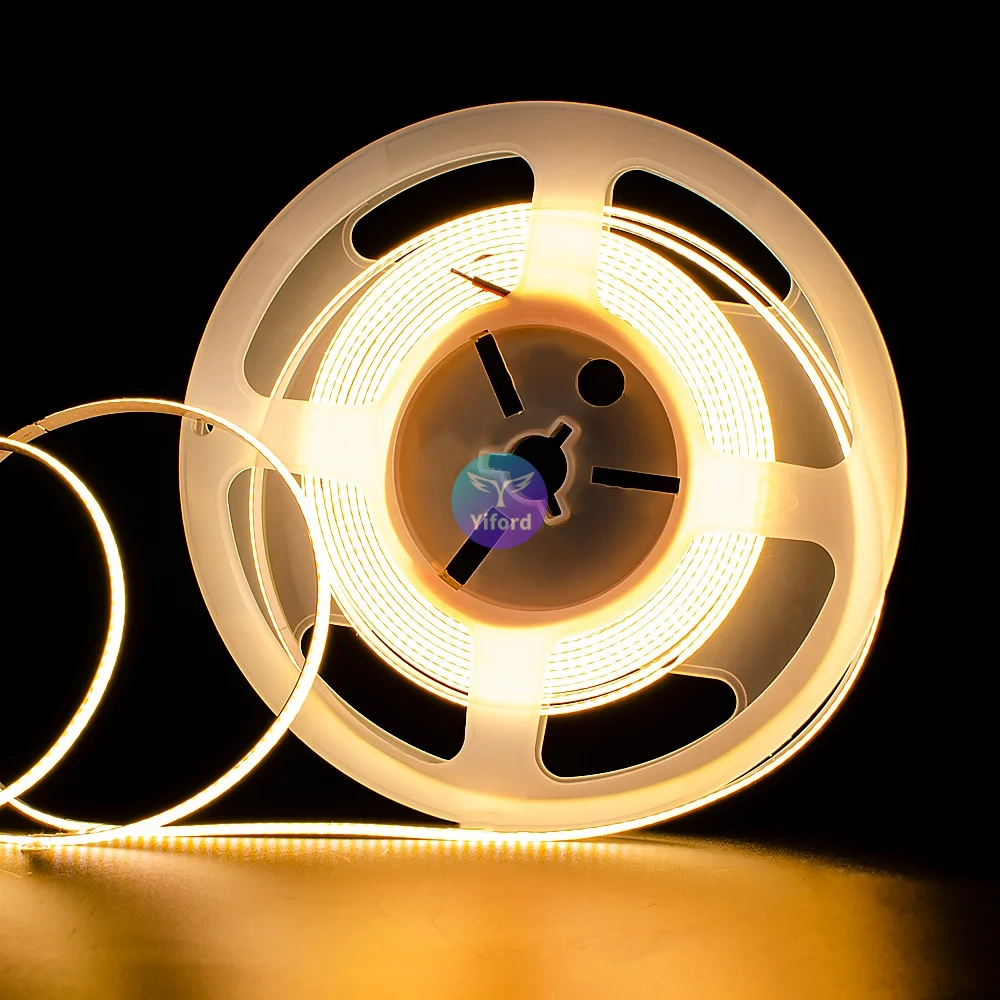

RGBIC Intelligent Addressable Colorful COB Light Strip

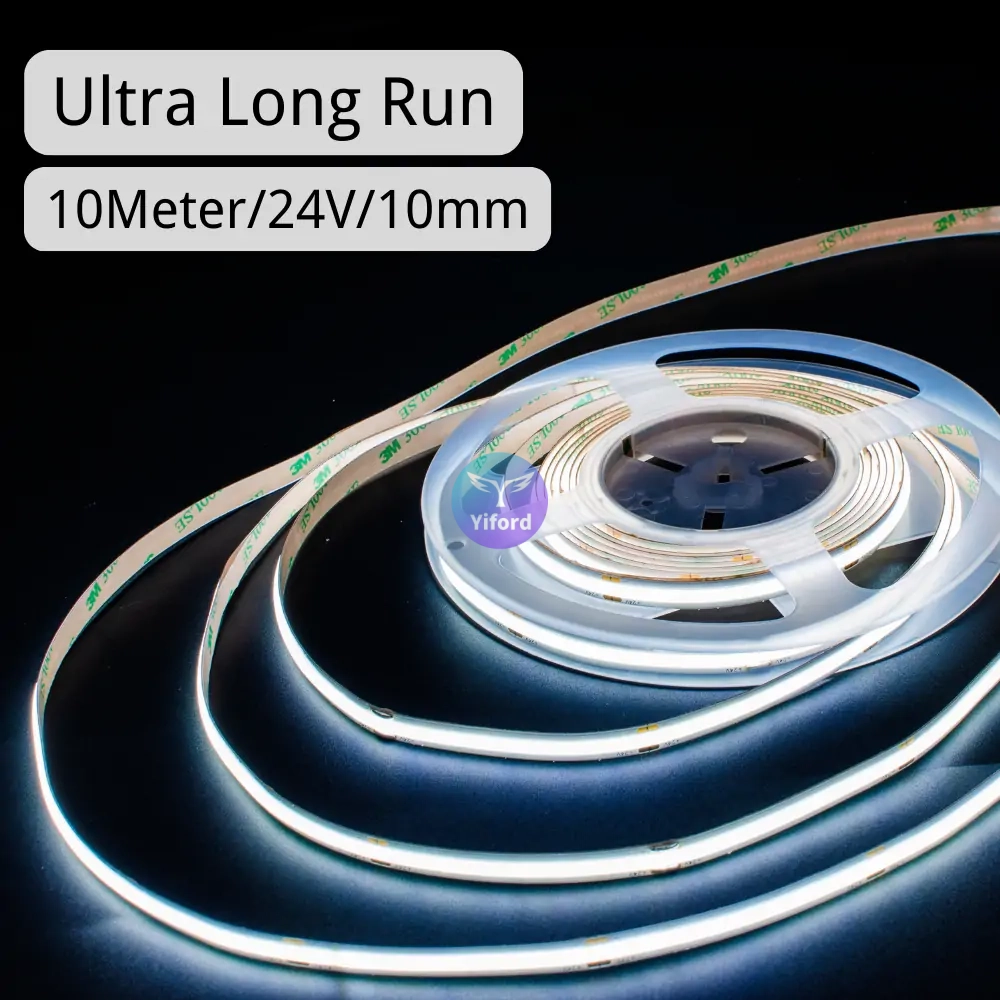

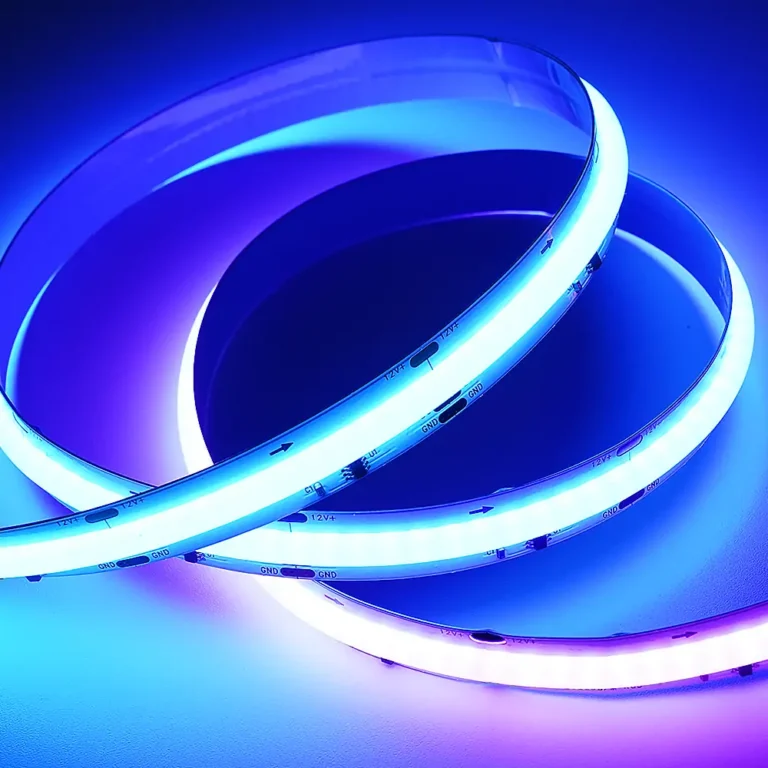

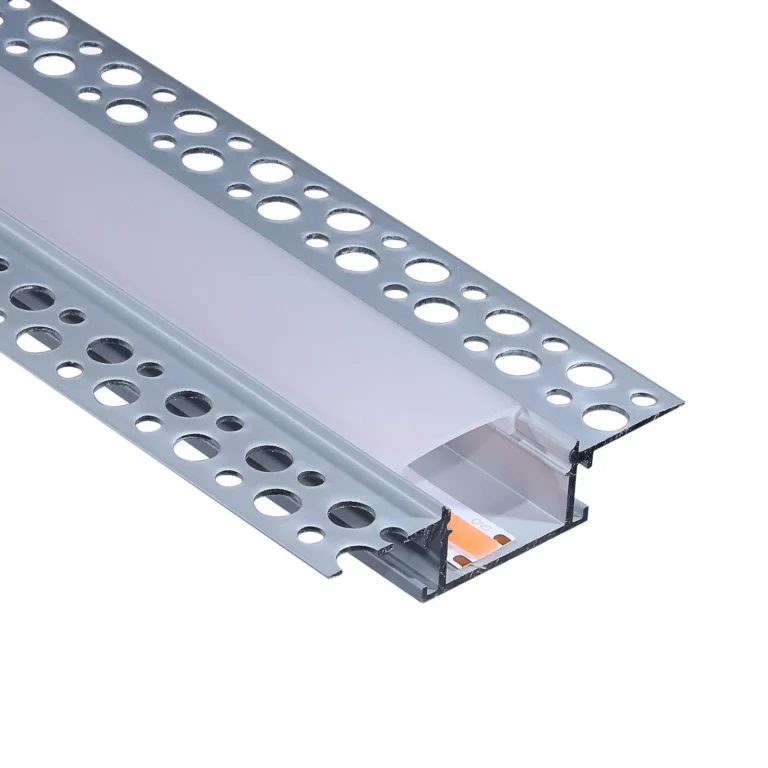

Elevate your commercial lighting projects with the YIFORD YF-CRGB10MM576-24V RGBIC Intelligent Addressable Colorful COB Light Strip. this cutting-edge light strip offers unparalleled versatility and performance. Discover how our advanced RGBIC technology and COB design can enhance your projects with seamless color transitions and uniform lighting. Explore the features, benefits, and applications of our high-density LED solution, and see why YIFORD is the trusted choice for professional lighting needs.

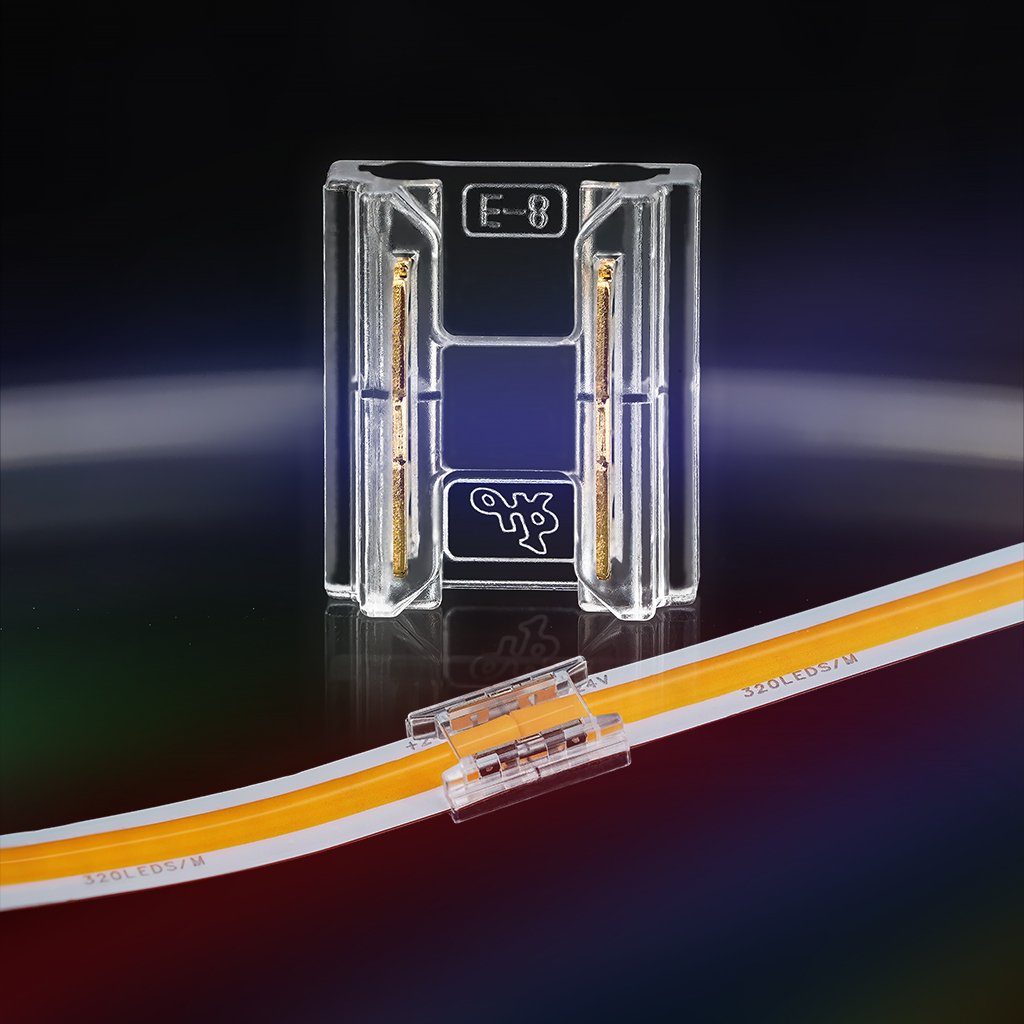

The most cost-effective connector for LED light strips

In the competitive LED lighting market, reliability and quality are paramount. YIFORD’s 4-in-1 solderless led connector for led light strips are engineered to deliver exceptional performance and build trust with your customers. Our comprehensive range and commitment to excellence make us the ideal partner for LED lighting distributors, manufacturers, and lighting installation companies…..

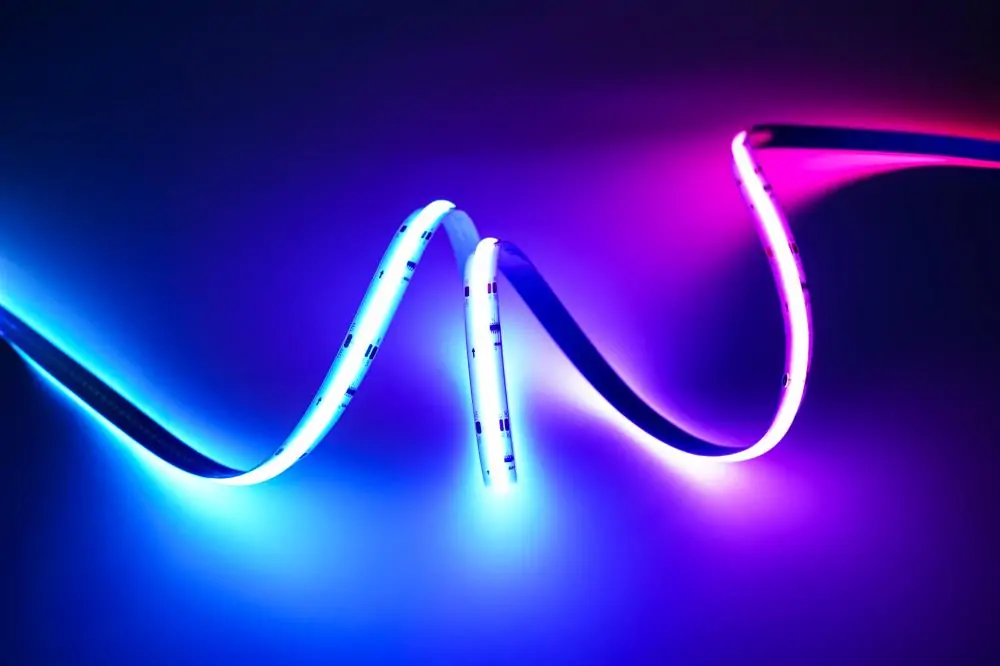

Addressable RGBIC COB LED strip lights

addressable rgbic cob led strip lights–magic dream color, dynamic life, wonderful continuous!

Today, I share a light strip, the magic chasing atmosphere light strip, the intelligent scene is rich, supports colorful e -sports light effects, full of atmosphere, and DIY is very playable.