RGBIC Intelligent Addressable Colorful COB Light Strip

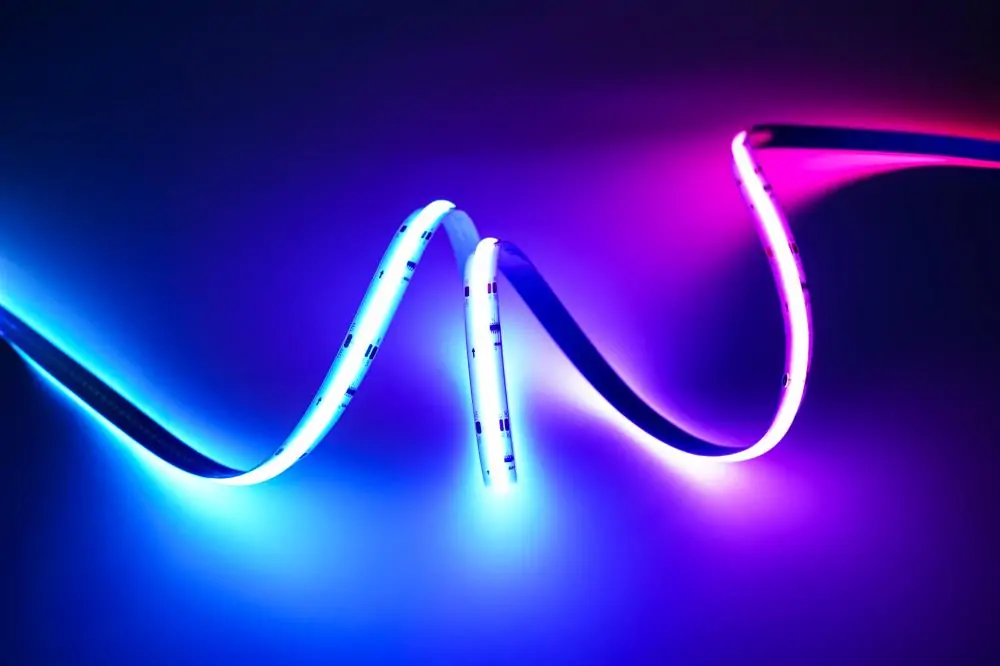

Elevate your commercial lighting projects with the YIFORD YF-CRGB10MM576-24V RGBIC Intelligent Addressable Colorful COB Light Strip. this cutting-edge light strip offers unparalleled versatility and performance. Discover how our advanced RGBIC technology and COB design can enhance your projects with seamless color transitions and uniform lighting. Explore the features, benefits, and applications of our high-density LED solution, and see why YIFORD is the trusted choice for professional lighting needs.

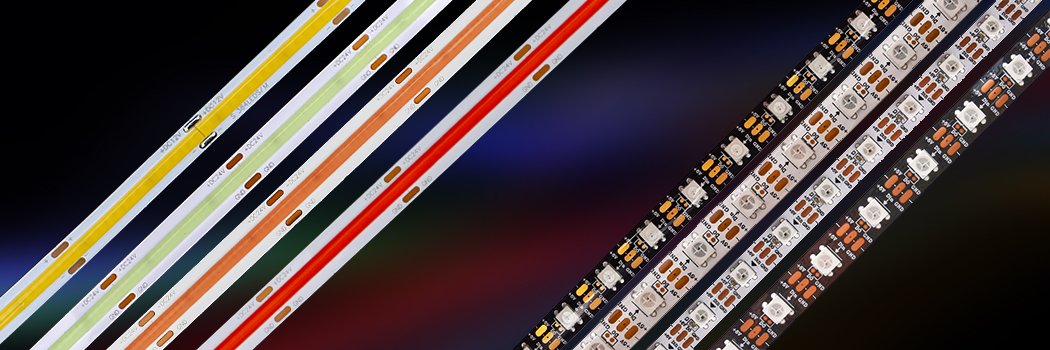

Round Tube

Round Tube

Topview Tube

Topview Tube

Sideview Tube

Sideview Tube

With Fringe

With Fringe

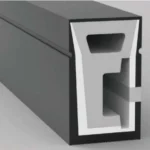

Black Tube

Black Tube

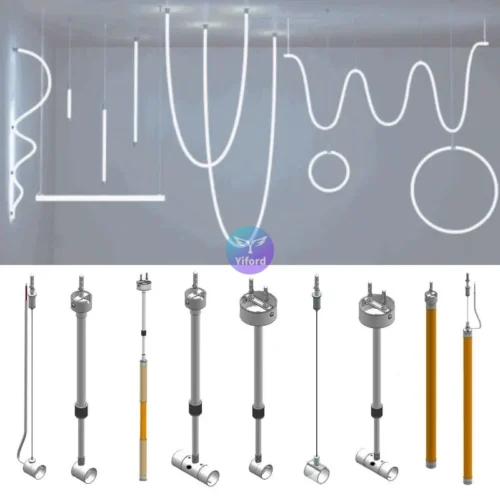

Light Accessories

Light Accessories